Target Utilization Is Only Half the Story

Target utilization is a common metric that manufacturers like to brag about, but the real question you should be asking is:

Of the precious metals you buy, how much is actually going onto your product?

And, more importantly:

How would you like to coat three to four times as much product with the same amount of precious metals?

Overall System Efficiency

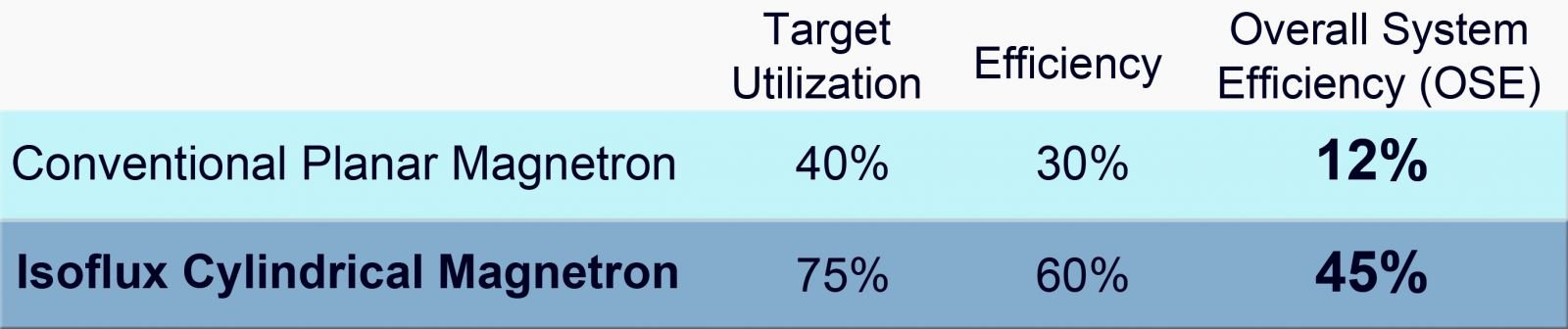

The full story requires examining both target utilization and efficiency. Target utilization measures how much of the target gets sputtered, efficiency measures how much of the sputtered material actually lands on the substrate. The combination is what we refer to as Overall System Efficiency (OSE) which measures how much of the metals you purchase actually lands onto your product.

Isoflux’ patented cylindrical magnetron design improves both target utilization and efficiency, resulting in up to FOUR TIMES the Overall System Efficiency compared to conventional planar magnetrons.

About Cylindrical Magnetrons

Isoflux's Hollow Cathode Magnetron Sources, also known as inverted magnetrons, use cylindrical targets to surround the substrate with coating materials. Ideal to coat complex, three dimensional shapes, wires, fibers and many other substrates, the cylindrical magnetron design is considerably more efficient than planar magnetrons and offers extremely high deposition rates, excellent target utilization, less down-time and simple maintenance.

The cylindrical design allows entire three dimensional items to be coated at once without the need for rotation The result is a more efficient and simple process. Unlike planar magnetrons, the magnetic field in the cylindrical magnetron produces uniform plasma and therefore leads to the more uniform use of materials. The cylindrical magnetron utilizes approximately 75% of the target because most of the deposition material that is not deposited on the substrate is redeposited onto the target.

This also means that the chamber does not need to be cleaned as often. Thus, you'll spend less money on expensive target materials, fewer hours replacing targets and enjoy reduced machine downtime.

NOTE: Target utilization and efficiency for the Isoflux cylindrical cathode are based upon a silver application, coating a 4 inch wide tape, passed through a 25cm long, 25cm diameter cathode. Efficiency is dependent upon the geometry and loading of parts for all magnetrons; however, cylindrical cathodes will always tend to perform better with complex geometries or three dimensional parts.